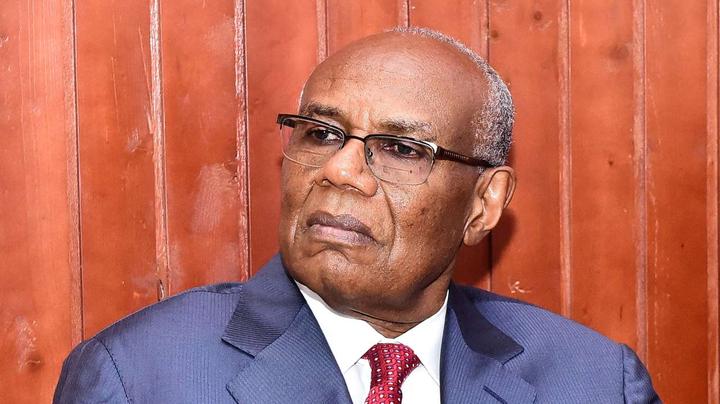

Former Managing Director, Kaduna and Port Harcourt Refineries, Alex Ogedengbe, has expressed reservations about the Nigerian government’s decision to rehabilitate the old Port Harcourt refinery in Rivers State, saying there won’t be any appreciable output from the plant.

The Federal Government had in March 2021 approved $1.5 billion contract for the rehabilitation of the refinery. The then Minister of State for Petroleum, Timipre Sylva, had said the rehabilitation would be done in three phases of 18, 24 and 44 months and funded through the Nigeria National Petroleum Company’s Internally Generated Revenue (IGR), Afrexim Bank and budgetary provisions.

Join our WhatsApp ChannelPrime Business Africa reports that the NNPC recently released a video where the MD of the Port Harcourt Refinery, Ibrahim Onoja, reassured that the refinery will be completed by December 2023 as earlier promised by the Federal Government.

READ ALSO: Oil Theft Continues To Frustrate Nigeria’s Efforts To Ramp Up Production

He disclosed that the procurement process for the facility is 98 per cent complete, adding that the refinery would engender competition once it comes on stream. “Our long lead items are on site; instrumentations are on site. We have completed most of the procurement that we need to do. The refinery has gone over 98 percent,” Onoja said in a video aired on Arise TV.

However, analysts have continued to express doubt about the possibility of having the refinery back to full operations by December 2023 as promised.

Ogedengbe, who featured on Channel Television Sunrise Daily on Tuesday morning, said the old Port Harcourt Refinery built in 1965, has only 60,000 barrels per day capacity, and would only produce about 30 per cent of what the new refinery which according to him, has 150,000 bpd capacity, could produce.

Ogedengbe, who is also an ex-president of the Nigerian Society of Chemical Engineers, said the best decision should have been to rehabilitate the new refinery which was built with modern technology and could produce more quantity of petroleum products needed for local consumption and even exports.

According to him, around 1991 when the Port Harcourt, Warri and Kaduna refineries were working fairly close to 78 percent capacity the country completely depended on locally produced petroleum and not a single drop of refined product was imported.

He said the old Port Harcourt Refinery has not operated for 30 years since 1990 when the new one came on stream. “I don’t expect an appreciable contribution from the refinery being rehabilitated,” he asserted.

Highlighting the difference between the old and new Port Harcourt refineries, the former MD said: “When the new refinery was designed, I was the project manager from 1985 to 1990. We had accommodated the old refinery in the design of the new one. We linked them and took what we could use in the old one, the 60,000 bpd, to feed into the new one.

“The new one is more complex. If you put one barrel of crude oil into the new one, 48 to 50 per cent of it would be premium Motor Spirit (PMS). For the old refinery, if you put one barrel of crude oil into it, you only get a maximum of 23 or 24 percent of petrol. This shows the complexity. The old refinery has just one conversion unit that can produce petrol, while the new refinery had four different conversion units.”

He queried why the old refinery was being rehabilitated instead of the new one which could produced in commercial quantity. “The old refinery was built in 1965 with different old technology,” he stated.

“You do not reconstruct 100 or 150-year-old refineries but put new ones with newer technologies. It is more difficult what they are doing now than what they should have done.”

He said it is only the contractor handling the project that can speak on the exact time for completion, expressing lack of confidence in what is being done.

Nigeria, according to reports, has imported more than 5.52 billion litres of petrol, since the removal of the petrol subsidy on May 30, 2023. Heavy reliance on imports has continued to put pressure on the naira leading to foreign exchange crisis and high cost of the commodity.

The Group Chief Executive Officer NNPCL, Mele Kolo Kyari had also assured that the Kaduna refinery would be completed by the end of 2024, and that would ensure be an end to petrol import in the country. But observers counter that saying that relying on only conventional refineries without encouraging the establishment of modular refineries will not help matters.

The Federal Government had at least in the last 18 years awarded over 50 refinery licences which they were in operation, which would have boosted the country’s refining capacity.

Reports indicate that many of the people who got refinery licences have no intention to refine crude oil.

Modular Refineries to the rescue?

Speaking on the state of modular refineries, Ogedengbe affirmed that many of the individuals or firms that got licences were merely to produce what they use in powering their plants not for commercial purposes. “Those licences were awarded on a different basis not to produce those products.”

According to him, there are five products that a standard refinery produces and modular refineries can’t produce all of them. “The five products standard in a refinery are LPG (Liquified Petroleum Gas), Kerosene, petrol, diesel and fuel oil. Those are the five standard products. All these modular refineries would only produce a part of it. The only one they produce in an appreciable quantity that can be used locally is diesel.

“The history is that most of the ones that started producing were for their consumption because they produce crude oil and they don’t have diesel for their, machines.”

He said the modular refineries today produce at best, kerosene, diesel, and naphtha. Naphta is an intermediate product used in producing petrol. According to him, it is a feedstock for petrochemical refineries and can also be used by plastic industries.

He maintained that a standard refinery is made up of several units and modular ones do not have those units.

He said those licensed modular refineries produce naphtha and export to petrochemical companies abroad for profit, which is not in the good interest of the country.

Victor Ezeja is a passionate journalist with seven years of experience writing on economy, politics and energy. He holds a Master's degree in Mass Communication.

Follow Us